Introduction

FILK offers clients the widest range of fire tests in Korea for the fire protection, construction, marine and other industries. As a KOLAS accredited laboratory, we can comprehensively test, predict and assess the fire performance of products and materials to various international test standards. Our fire tests may also form the basis of FILK Quality certification schemes or the requirements of other approval bodies, such as US Coast Guard, BV, and other shipping registers.

Classification

General testing : testing services to standards offered by clients through FILK quality system and test procedures Regulatory testing : testing for clients to enable them to demonstrate compliance with relevent standards and regulations set by the national and international approval bodies.

Test Products

| Team | Area | Contact | ||

|---|---|---|---|---|

| Tel. | ||||

| Risk and Safety Research Center | Combustion | Flame Propagation, Gas Hazard, Non-combustibility, Heat Emission Rate, | +82-31-887-6662 | jinmi@kfpa.or.kr |

| Smoke and Toxicity | +82-31-887-6652 | hsro@kfpa.or.kr | ||

| Physical Fire-Test for Architectural Finishing Materials (KF F 8414) |

+82-31-887-6675 | iidarkii@kfpa.or.kr | ||

| Fire-Fighting Equipment | Sensitivity, Operation, Heat Resistance, Impact, Corrosion, Internal Pressure, etc. | +82-31-887-6653 | bhan@kfpa.or.kr | |

| +82-31-887-6654 | kwark@kfpa.or.kr | |||

| Electric Fire | Sensitivity, Ambient Temperature, Power Voltage Fluctuations, Electrostatic Radiation, Impact, Humidity, etc. | +82-31-887-6673 | pst7203@kfpa.or.kr | |

| Fire | Flame Resistance, Fire Resistance Performance(Nuclear Power Plant/General Cable), Demonstration Test(Electrical Equipment) | +82-31-887-6673 | pst7203@kfpa.or.kr | |

| Fire extinguishing agent adaptability, energy storage system (ESS) | +82-31-887-6653 | bhan@kfpa.or.kr | ||

| Automotive fire resistance performance (fuel tank, battery pack) | +82-31-887-6655 | junesuklee@kfpa.or.kr | ||

| Fireproof Fire Protection Facilities | Fire Door | +82-31-887-6688 | jskim@kfpa.or.kr | |

| Fire Door Set, Hardware Test, Elevation Guide | ||||

| Beam, Floor, Column, High-Strength Concrete, Roof | +82-31-887-6685 | dhkim@kfpa.or.kr | ||

| Fire Door Quality Test, Damper, Window, Wall, Vault, Top-Down Evacuation Zone | +82-31-887-6684 | hwseo@kfpa.or.kr | ||

| Charging Structure, Fire Protection Shutter, Ships | +82-31-887-6719 | sjlee@kfpa.or.kr | ||

| Architectural Environment | Heat Flow/Condensation Prevention Performance | +82-31-887-6691 | gylee@kfpa.or.kr | |

| Watertightness/Airtightness/Wind Pressure Resistance | ||||

| Sound Absorption and Sound Insulation | +82-31-887-6737 | jhjeong@kfpa.or.kr | ||

| Noise Performance, Floor Impact Sound | ||||

| Construction Materials | Dust Amount, Panel Strength | +82-31-887-6697 | mjkim@kfpa.or.kr | |

| Fire Evacuation | Full-Scale Fire Safety | +82-31-887-6696 | kwpark@kfpa.or.kr | |

| Acoustic Diffusion Coefficient, Evacuation Acoustics | +82-31-887-6619 | ycshin@kfpa.or.kr | ||

| Renewable Energy Safety Research Center | Fire | Battery Demonstration Tests, etc. | +82-31-887-6663 | mwpark@kfpa.or.kr |

| +82-31-887-6656 | shl@kfpa.or.kr | |||

| +82-31-887-6659 | donghwankim@kfpa.or.kr | |||

Shipping Materials

FILK tests in accordance with IMO FTP Codes form the basis of the requirements of shipping approval bodies such as BV, etc.

| Team | Area | Test Method | Contact | |

|---|---|---|---|---|

| Tel. | ||||

| Risk and Safety Research Center | Part 1: Non-combustibility Test Part 2: Smoke & Toxicity Test Part 5: Test for Surface Flammability Part 6: Test for Primary Deck Converings |

ISO 1182:1990 As describe part2 Res.A.653(16) Res.A.653(17) |

+82-31-887-6662 | jinmi@kfpa.or.kr |

|

If you want more information about Part 2 : Smoke & Toxicity Test click here, Part 5 : Test for surface flammability, Part 6 : Test for primary deck coverings click here |

||||

| Risk and Safety Research Center | Part 3 : Test for "A","B" & "F" class division Part 4 : Test for fire control systems |

Res. A.754(18) As described in Part 4 | +82-31-887-6719 | sjlee@kfpa.or.kr |

USCG Type Approval Testing Service

FILK was accepted by USCG to conduct fire testing in accordance with IMO FTP Code Part 1, 3, 4, 5 and 6 for its Type-Approval Certification in August 2002, the first among the fire laboratories in Asia and one of the 15 laboratories worldwide approved by USCG. As a USCG accepted fire laboratory FILK, on behalf of USCG, conducts rigorous assessments and testing of the ship's articles such as insulations, fire doors, bulkhead panels, ceilings, deck assemblies, interior finishes, etc., and helps ensure, through FILK Follow-Up service, the quality system of the manufacturers that are certified by USCG.

| Team | Area | Test Method | Contact | |

|---|---|---|---|---|

| Tel. | ||||

| Risk and Safety Research Center | Part 1: Non-combustibility Test Part 2: Smoke & Toxicity Test Part 5: Test for Surface Flammability Part 6: Test for Primary Deck Converings |

ISO 1182:1990 As describe part2 Res.A.653(16) Res.A.653(17) |

+82-31-887-6662 | jinmi@kfpa.or.kr |

| Part 3 : Test for "A","B" & "F" class division Part 4 : Test for fire control systems |

Res. A.754(18) As described in Part 4 | +82-31-887-6719 | sjlee@kfpa.or.kr | |

TUV CERTIFICATION TEST(Fire resistant test of the plastic fuel tank for vehicles)

Fire resistant test of the plastic fuel tank for vehicles is to assess the fire resistance performance and air tightness of the fuel tank by heating the tank specimen directly and indirectly with gasoline for 2 minutes. Test equipment consists of fuel pan, screen, chassis transport, rail, and control panel

Fire Test Standards

- EEC Directive 70/221/EEC(Annex I/6.3.5)

- ECE Regulation 34(Annex 5/5)

Test Equipment

| ITEM | USE | SPECIFICATIONS |

|---|---|---|

| Fuel pan | Direct flaming | 1,600(L)×1,200(W), Steel |

| Screen | Indirect flaming | 2,300(L)×1,600(W), Blucks |

| Chassis Moving device | Moving chassis | 2,600(L)×2,300(W), Steel |

| Rail | Moving screen & fuel tank | 10m, Steel |

| Wireless control,Cabinet type | Controlling the equipment |

| Team | Contact | |

|---|---|---|

| Tel. | ||

| Risk and Safety Research Center | +82-31-887-6655 | junesuklee@kfpa.or.kr |

Crankcase relief valve performance test

Assess the performance of crankcase explosion relief valves intended to be fitted into engines and gear cases to the requirements by shipping approval bodies.

Fire Test Standards

- IACS UR M66. rev.3

Test Equipment

| ITEM | USE | SPECIFICATIONS |

|---|---|---|

| Test Vessel | For Relief Valve Installation & Explosion | 1,600(L)×1,200(W), Steel |

| FTIR | (9.5 ± 0.5)% Density Measurement of Gas | MIDAC CORPORATION FTIR-14001 |

| Pressure Equipment | Explosion Pressure Measurement | Dyno Ware Type KISTLER 2825A-02-2 |

| Therm Cam | Measurement of Flame Discharge | CEDIP SC 5000 |

| Control system | Collection of Data | Cabinet type |

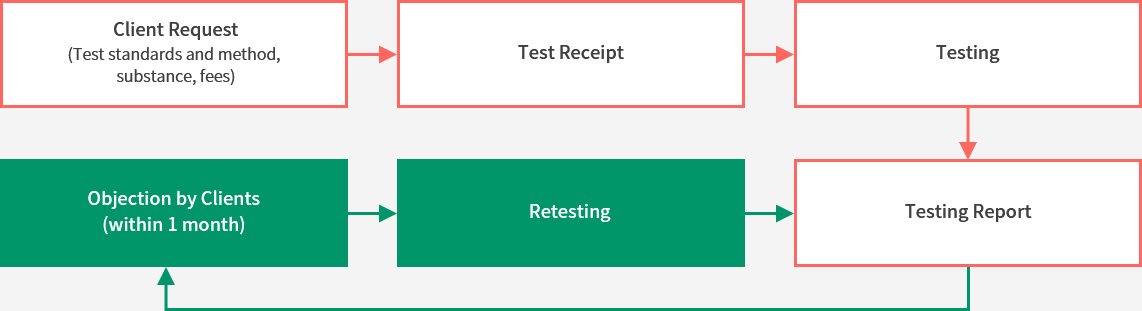

Test Procedures

Test procedures are as following, and products to be tested and fees should be sent to us before testing.

You can pay test fees through bank accounts or credit cards.

Contact with the relevant testing lab about the details such as fees and schedules you need.

* Korean Won is the standard currency in Korea, but foreigners may pay with USD. Payment should be completed within 7 days after you receive an estimate.

Smoke and Toxicity Test (IMO. FTP Code Part 2)

Where a material is required not to be capable of producing excessive quantities of smoke and toxic products or not to give rise to toxic hazards at elevated temperatures, the material shall comply with this test. The maximum specific optical density of smoke (Ds max) shall be obtained for each test. When making toxicity measurements, the sampling of fumes shall be made during the testing of the second and the third specimen at each test condition, from the geometrical centre of the chamber at the time when the maximum specific optical density of smoke is reached. The concentration of each toxic gas shall be determined as parts per million (ppm) in the chamber volume.

Performance criteria

| Surface of bulkheads, linings or ceilings | Primary deck coverings | Floor coverings | Plastic pipes | ||

|---|---|---|---|---|---|

| Dm* | ≤ 200 | ≤ 400 | ≤ 500 | ≤ 400 | |

| Toxicity | CO | ≤ 1,450 ppm | |||

| HBr | ≤ 600 ppm | ||||

| HCl | ≤ 600 ppm | ||||

| HCN | ≤ 140 ppm | ||||

| HF | ≤ 600 ppm | ||||

| SO2 | ≤ 120 ppm (200 ppm for floor coverings) | ||||

| NOx | ≤ 350 ppm | ||||

*Dm is An average (Dm) of the maximum specific optical density of smoke (Ds max) of three tests at each test condition

Specimen preparation and test fee

| Test method | Dimensions(mm) | Number required | Test fee | Remark |

|---|---|---|---|---|

| IMO. FTP Code Part 2(Smoke & Toxicity Test) | ength : 75(-1), width : 75(-1), thickness : ??25 |

12 | 2,613,000 KRW (3,135,600 KRW) | For performance verification test (For Ship register type approval test) |

[ Smoke Density Chamber ]

[ Gas analyzer(FT-IR) ]

Application procedures

- a)Sending the specimens and required documents including specification of the specimen.

- b)Transfering the test fees into an account belows:

- c)Specification and structure of the specimen materials should be informed prior to application.

Test for Surface Flammability(IMO. Res. a. 653(16) or 687(17))

Where a product is required to have a surface with low flame-spread characteristics, the product shall comply with this test. Where the primary deck coverings are required to be not readily ignitable, they shall comply with this test. The test method involves mounting the conditioned specimen in a well-defined flux field and measuring the time of ignition, spread of flame and its final extinguishment, together with a stack thermocouple signal as an indication of heat release by the specimen during burning. The following data shall be derived from the test results : CFE, Qsb, Qt and Qp.

Performance criteria

| Bulkhead, wall and ceiling linings | Floor coverings | Primary deck coverings | |

|---|---|---|---|

| CFE (kW/m2) | ≥ 20.0 | ≥ 7.0 | ≥ 7.0 |

| Qsb (MJ/m2) | ≥ 1.5 | ≥ 0.25 | ≥ 0.25 |

| Qt (MJ) | ≤ 0.7 | ≤ 2.0 | ≤ 2.0 |

| Qp (kW) | ≤ 4.0 | ≤ 10.0 | ≤ 10.0 |

| Burning droplets | Not produced | No more than 10 burning drops | Not produced |

*Where:

- CFE = Critical flux at extinguishment

- Qsb = Heat for sustained burning

- Qt = Total heat release

- Qp = Peak heat release rate

Specimen preparation and test fee

| Test method | Dimensions(mm) | Number required | Test fee | Remark |

|---|---|---|---|---|

| 1. IMO. Res. A. 653(16)> 2. IMO. Res. A. 687(17) | length : 800(-5) width : 155(-5) thickness* | 6 | 1,605,500 KRW (1,926,600 KRW) | For performance verification test (For Ship register type approval test) |

* Materials and composites of normal thickness 50 mm or less shall be tested using their full thickness. For materials and composites of normal thickness greater than 50 mm, the required specimens shall be obtained by cutting away the unexposed face to reduce the thickness between 47 mm and 50 mm.

[ Smoke Density Chamber ]

Application procedures

- a)Sending the specimens and required documents including specification of the specimen.

- b)Transfering the test fees into an account belows:

- c)Specification and structure of the specimen materials should be informed prior to application.